Precast Stream Crossings

ConSpan Bridges

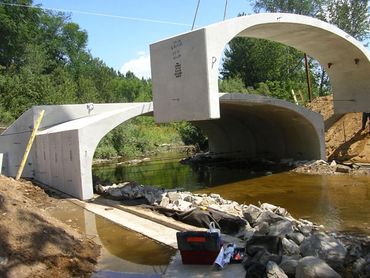

U.P. Concrete Pipe Company manufactures the Con/Span® 3-Sided Bridge Arch Culvert at its manufacturing facility in Escanaba, Michigan. This patented precast bridge system has been shipped to jobsites throughout the Upper Peninsula of Michigan and Northern Wisconsin.

Con/Span® is a patented modular precast 3-sided bridge system designed for total set-in-place construction and can be used for bridges, underground structures and environmentally acceptable alternatives for underground containment.

Each installation is custom designed and manufactured according to your specific site requirements.

Precast modular units are delivered to your jobsite and set in place by a crane.

U.P. Concrete Pipe Company has the ability to produce architectural treatments to the wingwalls and headwalls of these bridges, enhancing the beauty and aesthetics while not affecting the structural integrity of the bridge.

The Con/Span® units can be set on precast or cast-in-place footings, on a precast slab bottom, on a pedestal wall, or on pile caps.

Precast strip footings preserve the natural stream bottom and also allow water percolation in retention vaults.

Standard size wingwalls, designed for your specific site, are furnished in one piece, are self supporting and can be backfilled immediately after installation. Larger wingwalls are manufactured in multiple sections to facilitate shipping and handling.

Advantages

- The arch shape provides you with an economy of materials for a lower initial cost

- Overall savings for a project are significant when compared to cast-in-place

- Has a fast installation time, usually within hours. This minimizes road closings, detour times and maintenance of traffic, which results in significant cost reductions

- Eliminates 2 major problems associated with other bridge designs; costly maintenance of an exposed bridge deck and bridge deck icing

- Off-site fabrication ensures product will have tight adherence to design specifications through quality control of each modular unit manufactured

- Product has a long life cycle, low life cycle costs and virtually no maintenance after installation

- Various decorative treatments available

Box Culverts

U.P. Concrete Pipe Company manufactures a wide range of precast concrete box culvert sizes unique to each specific project. These box culverts have been used for stream crossings, pedestrian tunnels, snowmobile tunnels and stormwater retention & detention chambers throughout the Upper Peninsula of Michigan and Northern Wisconsin. With its wide variety of precast box culvert forms, U.P. Concrete Pipe Company also has the ability to manufacture tapered end sections and angled/skewed pieces as well.

UPCPC precast box culverts are manufactured according to plan size and details, and will meet the specifications required for each unique project. All reinforced precast concrete box culverts conform to ASTM C1577 (LRFD HL93 Michigan modified), ASTM C1433, BOXCAR or job specific design criteria.

There are other possible applications for precast concrete box units as well, which include but are not limited to a vertical box structure application. Please contact our knowledgeable Sales & Engineering staff to discuss the possibilities.

Advantages

- The arch shape provides you with an economy of materials for a lower initial cost

- Overall savings for a project are significant when compared to cast-in-place

- Has a fast installation time, usually within hours. This minimizes road closings, detour times and maintenance of traffic, which results in significant cost reductions

- Eliminates 2 major problems associated with other bridge designs; costly maintenance of an exposed bridge deck and bridge deck icing

- Off-site fabrication ensures product will have tight adherence to design specifications through quality control of each modular unit manufactured

- Product has a long life cycle, low life cycle costs and virtually no maintenance after installation

- Various decorative treatments available

3-Sided Box Culverts

U.P. Concrete Pipe Company introduced its 3-sided small span box culvert in 1998. Our Small Span is environmentally sensitive and leaves the stream bed with little to no encroachment. With the Small Span 3-Sided Box Culvert, footings can be precast at our manufacturing facility, or poured-in-place on site. Either of these footing options result in a quick installation.

Precast Reinforced Concrete 3-Sided Small Span Bridge

6′ thru 20′ span x 4′ rise, Small Span Box Culvert Manufactured According to Plan Detail.

The Small Span 3-Sided Box Culvert is structurally sound and withstands construction loads better than metal. It also resists corrosion on both the invert & soil side, unlike metal. Additionally, it’s not affected adversely to weathering, wear and fire when compared to timber bridges.

Another advantage of the Small Span 3-Sided Box Culvert is its very long service life, typically 100 years, or 2 to 4 times longer than that of metal or timber bridge options.

The Small Span has a proven and conservative design, it’s economical, and it’s competitively priced at installation. When service life is considered, Small Span is the most economical compared to other alternatives.

Contact U.P. Concrete Pipe Company and we’ll help you complete a Least Cost Analysis (LCA) comparing our Small Span 3-Sided Box Culvert to alternative small span options.

Advantages

- Environmentally sensitive

- Withstands construction loads better than metal

- Corrosion resistant

- Long service life

LowSpan

LowSpan is a prestressed top slab, reinforced precast 3-sided culvert, bridge, or tunnel.

LowSpan provides longer clear spans due to its prestressed top slab. Prestressing provides longer span lengths with shallower rise heights creating maximum hydraulic efficiency. With conventional reinforcing alone, other 3-sided structures require thicker top slabs and/or geometry that can prohibit their use in long span and/or low height, site specific applications.

Three-sided structures provide a natural stream bottom which offers the benefit of hydraulic efficiency and no interference with the aquatic organisms and fisheries during and after construction. Further, 3-sided structures eliminate bridge deck maintenance and may reduce bridge icing concerns as well.

Advantages

- Longer span lengths (45’ – 60’) Shorter or taller rise heights

- Maximum end area due to optimum span to rise configuration

- More aesthetic appeal due to slender sections

- Weight reduction assists in shipping as well as handling at job site

- Ability to address restrictive high & low chord elevations of a bridge

U.P. Concrete Pipe Co.

6480 US-2 & 41, Escanaba, MI 49829 (Ship) | P.O. Box 313, Escanaba, MI 49829 (Mail)

Copyright © U.P. Concrete Pipe Company. All Rights Reserved.

Website by gopixelpro.com